- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

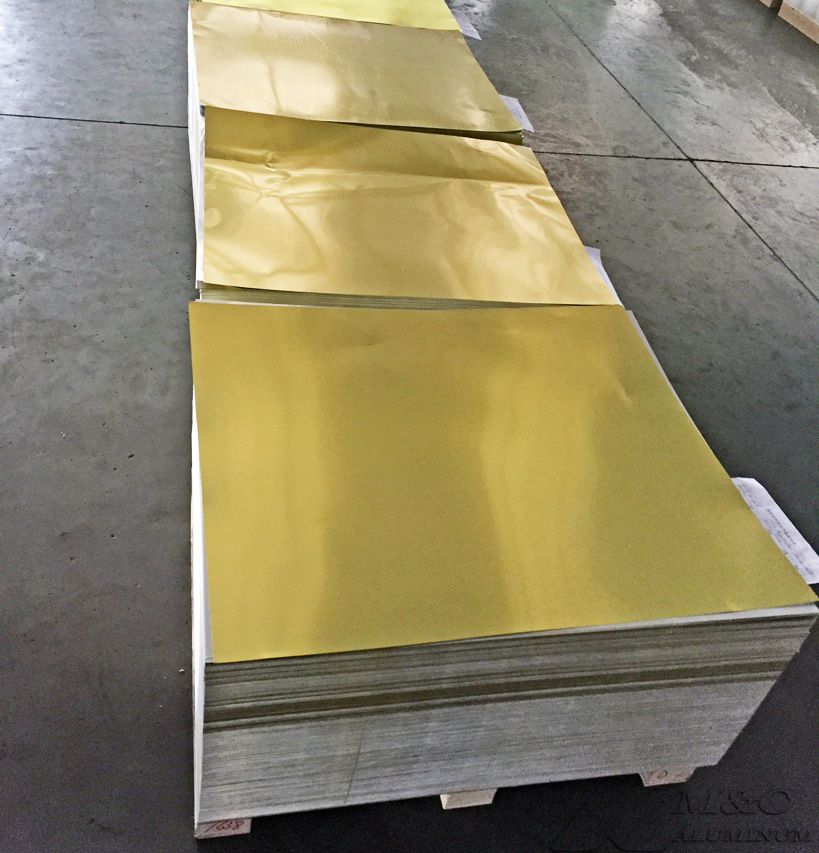

3105 8011 H14 / H16 bottle cap aluminum sheet

Aluminum has become an ideal material for manufacturing bottle caps because of its good formability, sealing properties and corrosion resistance. In addition, aluminum closure sheets have good deep drawing and tensile properties and are suitable for manufacturing anti-theft bottle caps that require deep drawing and forming. Usually used for sealed packaging in food, beverages, pharmaceuticals and other fields.

Commonly used alloy grades for bottle cap aluminum sheets include 1060, 8011, 3105, 1235, 1070, 5052, etc. These alloys have different performance characteristics.

Advantages of aluminum sheet for bottle cap sealing:

Surface quality: The surface must be flat and free of rolling marks, scratches and stains to facilitate subsequent printing.

Sealing performance: Aluminum bottle caps have good sealing properties, ensuring the quality and safety of packaging contents.

Corrosion resistance: Aluminum sheets have certain corrosion resistance and can resist external environmental erosion.

Lightweight and high strength: Aluminum is lightweight and strong enough to maintain the seal of the bottle cap.

Good forming performance: Aluminum is easy to stamp and bend, and can be made into bottle caps of different shapes.

Aluminum closure sheet specifications for bottle caps

| Alloys | 8011, 3105, etc |

| Temper | H14, H16, H18,etc |

| Thickness (mm) | 0.16-0.23, thickness tolerance +/-0.005mm |

| Width (mm) | 100-1500, width tolerance +/-0.005mm |

| Length (mm) | C |

| Surface | Dos oil treatment, chroming, painting, coating, printing, smooth finish (optional) |

| Typical products | aluminum white wine bottle caps, red wine bottle caps, wine pp bottle caps, screw caps, etc. |

Package:

Panels: Aluminum-sealed panels are placed in wooden boxes with slide rails along the length of the panels. The boards are wrapped in high-density polyethylene and have cardboard at the top and bottom of the pile. Iron bands are wrapped along the length of the board. Put a silica gel bag in the box to prevent moisture.

Rolls: Rolls are placed on wooden pallets at sky level or wall level, wrapped with HDPE fabric and cardboard, and tied with iron hoops. Use silicone packs to protect against moisture.

MC Aluminum specializes in the production of aluminum alloy bottle cap materials. It is the raw material source for aluminum cap material factories at home and abroad. It has ten casting and rolling production lines, one 1+4 hot rolling production line, six 2450mm\2050mm\1650mm\1450mm cold rolling production lines, and three 1650mm foil rolling production line, two 1850mm continuous rolling production lines, a quenching furnace, a tension pre-stretching machine, as well as presses, double-sided milling, cutting machines, rewinding machines, grinders, lathes, casting pits, and annealing furnaces , smelting furnace and other equipment.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan