- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

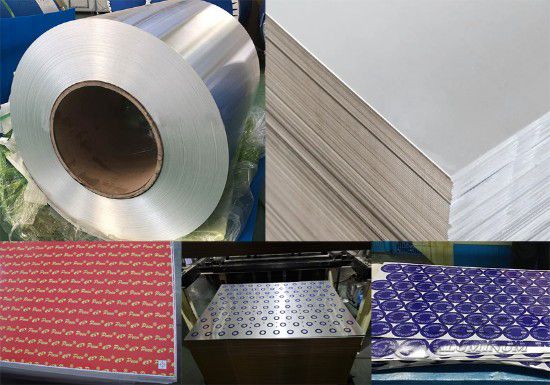

Aluminum alloy for pp cap material

MC Aluminum supplies aluminum sheets and coils for the manufacture of bottle caps, which are ideal materials for PP caps for whiskey bottles and other beverage bottles. It has excellent moisture-proof, anti-seepage and anti-counterfeiting properties, and is truly safe, healthy, fast and environmentally friendly, which increases the added value of the product.

The production of pp bottle caps has strict requirements on the strength, elongation and dimensional deviation of the material, otherwise cracks or creases will appear during the processing. In order to ensure the convenience of printing after the bottle cap is formed, the surface of the bottle cap material is required to be smooth. Free of roll marks, scratches and stains. Generally used alloys are 8011-H14, 8011-H16, etc. The production of aluminum bottle cap materials can be produced by hot rolling, continuous casting, continuous rolling, or cold rolling.

Aluminum pp cap sheet specifications:

| Alloy | 8011 |

| Temper | H14, H24, H16, H26 |

| Thickness | 0.16mm-0.23mm |

| Width | 50mm-1500mm |

| Length | 500mm-1500mm |

| ID (inner diameter) | 76mm, 152mm, 300mm, 350mm, 508mm |

| Surface | rolled, degreased, pre-lubricated, pre-treated, painted |

| Bus coil | CC (continuous casting), DC (direct casting) |

PP bottle cap material features:

1. Light weight.

2. Green, environmentally friendly and easy to recycle.

3. Has excellent barrier properties.

4. Has good formability

5. Beautiful appearance, providing bright finish for decoration.

Related Articles

- Aluminum printed plate for Ropp cover 8011 3105

- Aluminum strip for can pull tab 5182

- 8011 heat-sealed aluminum foil for easy-peel milk powder can lid

- What kind of aluminum alloy is the aluminum alloy bottle cap

- High quality requirements for aluminum plates for bottle caps

- 3104 3105 bottle cap material aluminum sheet

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan