- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

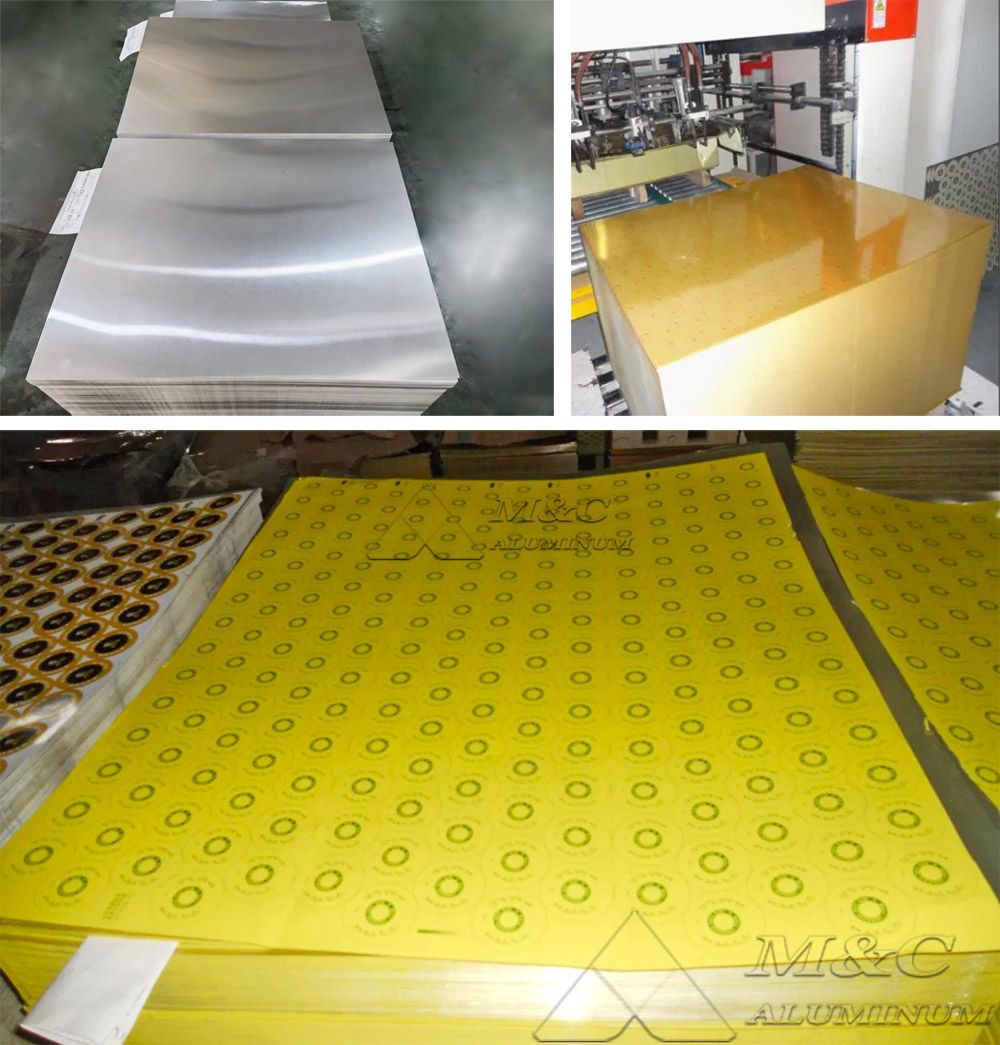

8011 Cast-Rolling Aluminum Sheet for Deep-Drawn Wine Bottle Caps

In the field of wine packaging, deep-drawn aluminum bottle caps are highly favored by premium liquor brands for their elegant metallic texture, excellent sealing performance, and adaptability to diverse printing and decoration processes. Among all materials, 8011 aluminum sheet, produced by the cast-rolling process, has become one of the most widely used materials for deep-drawn bottle caps due to its unique combination of formability, strength, and cost-effectiveness.

About 8011 Aluminum Alloy

8011 aluminum alloy belongs to the 8xxx series Al-Fe-Si alloys, featuring excellent deep-drawing capability and moderate strength, making it especially suitable for complex forming processes. It is extensively used in the production of beer caps, wine closures, spirit bottle caps, and health supplement lids.

Why Choose 8011 Aluminum Sheet for Bottle Caps?

1. Exceptional Deep-Drawing Performance

8011 aluminum sheet offers superior plasticity and high elongation, allowing uniform deformation during deep drawing without cracking, wrinkling, or orange-peel effects. This ensures high production yield and excellent forming consistency.

2. Balanced Strength and Toughness

While maintaining outstanding formability, 8011 alloy also provides sufficient strength. This balance ensures that the finished cap remains rigid enough to resist deformation during transportation and capping, yet flexible enough to tightly grip the bottle neck.

3. Excellent Corrosion Resistance

Naturally protected by a dense oxide film, 8011 aluminum alloy resists corrosion from both internal contents and external environments, maintaining a clean, rust-free appearance over time.

4. Superior Sealing Capability

For alcoholic beverages, sealing is critical to prevent leakage and oxidation. With its compact and uniform microstructure, 8011 aluminum forms a reliable barrier when combined with liners such as PVC or plastic drip seals, ensuring excellent airtightness.

5. Outstanding Surface Treatment Performance

8011 aluminum sheets can easily undergo printing, coating, and anodizing, making them ideal for decorative and anti-counterfeiting finishes required by premium liquor packaging.

6. Cost Efficiency

Compared with higher-purity alloys, 8011 offers a better balance of performance and price, making it the optimal choice for large-scale cap manufacturing.

Specifications of 8011 Aluminum Closure Sheet

| Thickness | 0.18-0.30 mm (customizable) |

| Width | 500-1500 mm (customizable) |

| Length | Coil or sheet per customer requirement |

| Tensile Strength | 90-120 MPa |

| Elongation | ≥25% |

| Hardness | 25-35 HB |

| Surface Finish | Mirror, brushed, coated, or anodized |

| Aluminum Content | ≥98% |

| Applications | Beer, wine, spirits, and health supplement bottle caps |

| Sample | Available |

| MOQ | 1-3 tons |

Cast-Rolling Process for 8011 Aluminum Sheet

Traditional hot-rolling processes-rolling thick ingots into thin sheets-require multiple steps, consume large amounts of energy, and often lead to higher costs and lower yields. In contrast, the cast-rolling process simplifies production, improves efficiency, increases yield rates, and reduces dependence on energy-intensive hot-rolling lines.

1. High-Purity Aluminum Melting

Pure aluminum ingots are melted in furnaces, refined, and degassed to ensure high purity and metal uniformity.

2. Casting and Rolling

Molten aluminum is solidified and rolled simultaneously in a continuous casting and rolling machine, forming aluminum sheets with uniform thickness and fine grain structure-ideal for deep drawing.

3. Homogenizing and Annealing

The cast-rolled sheets undergo controlled annealing to release internal stress, enhance plasticity, and improve formability, ensuring smooth deep drawing without cracks or wrinkles.

4. Surface Treatment

Optional finishes such as mirror polishing, brushing, or coating are applied to prepare the surface for printing, lacquering, or anodizing.

5. Precision Cutting and Packaging

Sheets are cut to precise dimensions suitable for cap punching, then moisture- and oxidation-proof packaging ensures safe transport and long-term storage.

The resulting 8011 cast-rolled aluminum sheets exhibit uniform thickness, smooth surfaces, high elongation, and excellent deep-drawing performance-perfectly meeting the demands of wine and liquor cap manufacturing.

Quality Control for 8011 Aluminum Closure Sheet

Chemical Composition: Strict Fe/Si ratio control to achieve optimal formability.

Mechanical Properties: Hardness, tensile strength, and elongation must remain within stable, specified ranges.

Thickness Tolerance: Uniform thickness ensures consistent stamping and cap dimensions.

Surface Quality: Must be free from scratches, oil stains, or oxidation spots.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan