- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

8011 pharmaceutical packaging aluminum closure cap

8011 pharmaceutical packaging aluminum cap is a high-quality pharmaceutical packaging material with the characteristics of good sealing, easy opening, beautiful appearance and anti-counterfeiting function. It has broad application prospects in the field of pharmaceutical packaging.

8011 aluminum foil for pharmaceutical bottle caps is commonly used in the state of H14/H16, with a thickness range of 0.15-0.27mm. It has excellent moisture-proof performance, light-shielding and high barrier ability, and can effectively block air and moisture to ensure the preservation quality of medicines. In addition, 8011 aluminum foil is also non-toxic, odorless, safe and hygienic, and meets the high standards of pharmaceutical packaging materials. It is widely used in the sealing of bottled liquids such as antibiotics, injections, oral liquids, etc.

Medical aluminum closure cap production process:

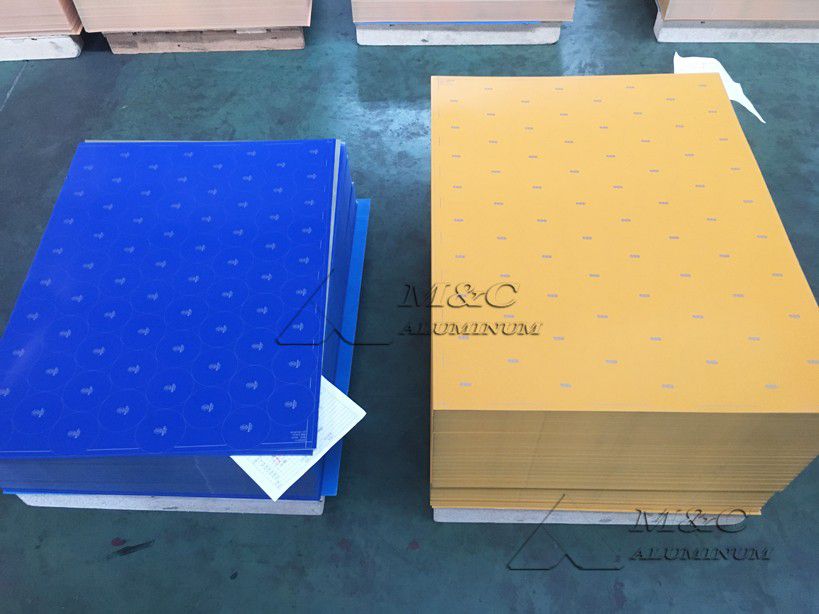

The production process of 8011-H16 bottle cap material is complicated and needs to be completed through multiple processes such as cold rolling, foil rolling, annealing, bending and straightening, and slitting. After the finished roll is produced, it needs to go through multiple processes such as cutting, painting, drying, multiple stamping, anti-counterfeiting logo, etc., and finally produce qualified aluminum alloy bottle cap materials.

Specifications of aluminum foil for medical bottle caps:

| Alloy | 8011 |

| Temper | H14, H16 |

| Thickness | 0.016-0.5mm |

| Width | 100-2160mm |

| Length | 100-16000mm |

| Surface | Printable color, customizable logo. |

| Application | used for beverage bottles, syrup bottles, and medicinal glass bottles. |

MC Aluminum is a professional aluminum alloy bottle cap material manufacturer. My main product is the raw material required for the production of aluminum caps, flip caps, anti-theft caps, easy-tear caps and other products---aluminum closure sheets. During the production process, the aluminum foil is strictly tested and quality controlled, including porosity inspection, heavy metal and bacteria inspection, to ensure that the aluminum foil meets the safety and hygiene standards for pharmaceutical packaging materials.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan