- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

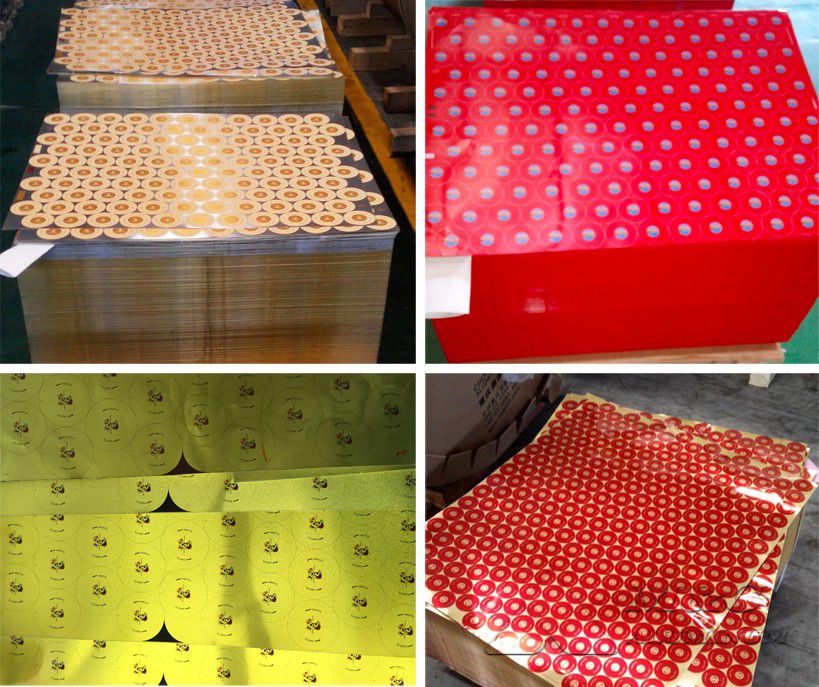

Printed aluminum sheets for bottle caps

Printed aluminum sheets are often used in the production of bottle caps, especially in the food, beverage, pharmaceutical and other industries. Aluminum sheets have the characteristics of light weight, strong corrosion resistance, good closure performance, etc., which can effectively protect the product, prevent the outside air or pollutants from entering the container, and extend the shelf life of the product.

Before printing, the surface of the aluminum closure sheet may need to be pre-treated, such as cleaning, degreasing, passivation, etc., to improve the adhesion of the printing ink and the printing effect. MC Aluminum can design the pattern, text, color, etc. of the bottle cap according to the product brand, market demand and consumer preferences.

Printed aluminum sheet specifications:

| Alloy | 8011 |

| Temper | H14, H24, H16, H26 |

| Thickness | 0.18-0.3mm |

| Width and length | cut according to customer requirements |

| Color | various colors can be provided according to customer requirements |

| Pattern | rolling, degreasing, pre-lubricating, pre-treatment, painting |

| Production process | DC/CC |

| Packing details | wooden box or plastic packaging |

Mechanical properties of aluminum closure sheet CC material

| Alloy | 8011 |

| Temper | H14 |

| Thickness (mm) | 0.16~0.23 |

| UTS (Mpa) | 185~205 |

| Elongation (%) | >=2 |

Mechanical properties of aluminum closure sheet DC material

| Alloy | 8011 |

| Temper | H14 |

| Thickness (mm) | 0.16~0.23 |

| UTS (Mpa) | 125~155 |

| Elongation (%) | >=2 |

Printed aluminum bottle caps have multiple advantages:

1. Aesthetics: Products can be beautified and attractive through electrochemical aluminum hot stamping and other technologies.

2. Anti-counterfeiting: Unique patterns and text can be used as anti-counterfeiting features to protect intellectual property rights.

3. Durability: Aluminum sheets are high in strength and resistant to transportation and stacking, ensuring product integrity.

4. Environmental protection: Aluminum sheets are recyclable, reducing environmental pollution and complying with the concept of sustainable development.

Application areas of printed aluminum seals:

Food and beverages: Aluminum bottle caps for beer, carbonated beverages, bottled water, juice, etc.

Medicines: Pharmaceutical bottle caps with high closure requirements, such as antibiotics, oral liquids, etc.

Cosmetics: closure of high-end cosmetic bottles to prevent pollution and oxidation.

MC Aluminum, as a manufacturer of aluminum bottle caps, provides 8011, 3105 and other aluminum alloys for the production of bottle caps. The product quality is stable and exported to many countries and regions. It can undertake orders of 1-2000 tons, direct sales from the manufacturer, and preferential prices.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan