- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

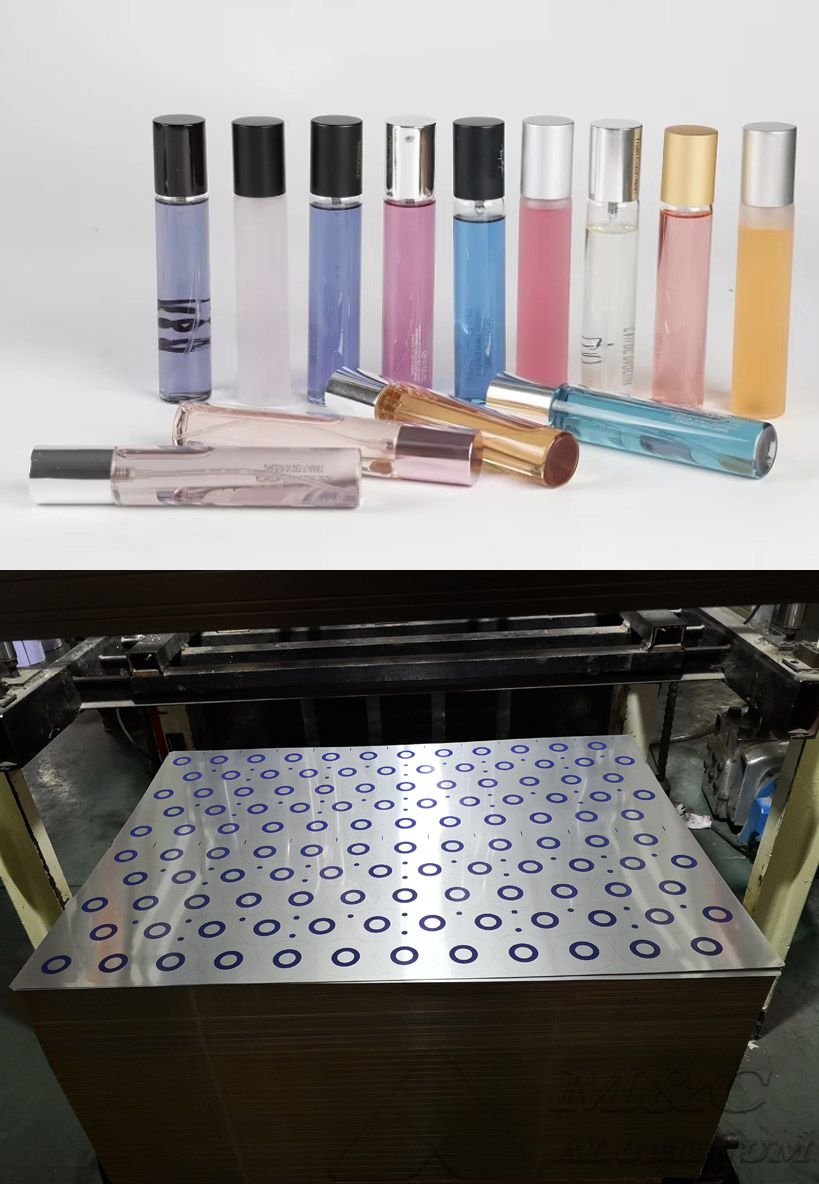

Aluminum alloy perfume bottle caps are safe and non-toxic

In perfume packaging design, the bottle cap is not only an important functional component, but also a key detail that reflects the brand's texture and high-end image. Aluminum alloy has become a popular choice in perfume bottle cap manufacturing due to its superior performance and diverse processing possibilities. Whether it is glossiness, durability, or environmental protection properties, aluminum alloy materials can meet the dual pursuit of design and quality of perfume brands.

The commonly used aluminum alloy grades for perfume bottle caps mainly include 1060, 3003, 8011, etc.

Advantages of aluminum bottle cap materials for perfume:

1. High-end and beautiful appearance

(1) Aluminum alloy has a metallic luster. After polishing, oxidation or spraying, the surface can be matte, glossy or a variety of colors, which looks high-end and elegant.

(2) Aluminum alloy has high design flexibility and can create complex and exquisite bottle cap shapes to meet the personalized needs of the brand.

2. Lightweight and strong

Aluminum alloy is light and easy to carry, but it has high strength and good durability. Compared with plastic, aluminum alloy is harder and can better protect the bottle cap and the internal perfume.

3. Excellent anti-corrosion performance

After the aluminum alloy is oxidized, a protective film is formed on the surface, which can effectively prevent corrosion and will not react chemically when in contact with perfume ingredients.

4. Environmentally friendly and recyclable

Aluminum alloy is a recyclable material. Compared with disposable plastics, it conforms to the current trend of environmental protection and sustainable development.

5. Strong sealing

It has high processing precision and can fit tightly with the bottle mouth. With the sealing design, it can effectively prevent perfume volatilization and external pollution.

Production process of aluminum alloy perfume bottle cap:

(1) Casting and molding: Aluminum alloy materials are made into bottle cap shapes through casting, stamping, CNC processing, etc.

(2) Surface treatment

Polishing/brushing: Improve surface gloss and texture.

Anodizing: Enhance surface hardness and corrosion resistance, and can also be colored.

Spraying/electroplating: Add decorative effects, such as high gloss, matte, metallic color, etc.

(3) Assembly and testing: Assemble the aluminum alloy bottle cap with the inner cap or seal to ensure that the air tightness and product performance meet the requirements.

Related Articles

- 3105 Aluminum Closure Sheet for Beverage Container Caps

- 8011 anti-theft bottle cap aluminum sheet

- Aluminum coil is the first choice for bottle cap material

- Aluminum foil for cosmetic bottle caps

- 1060 3105 5052 8011 Aluminum Closure Sheet for Bottle Caps

- 8011 H14 Lacquer Aluminum Coil for Bottle Caps

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan