- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

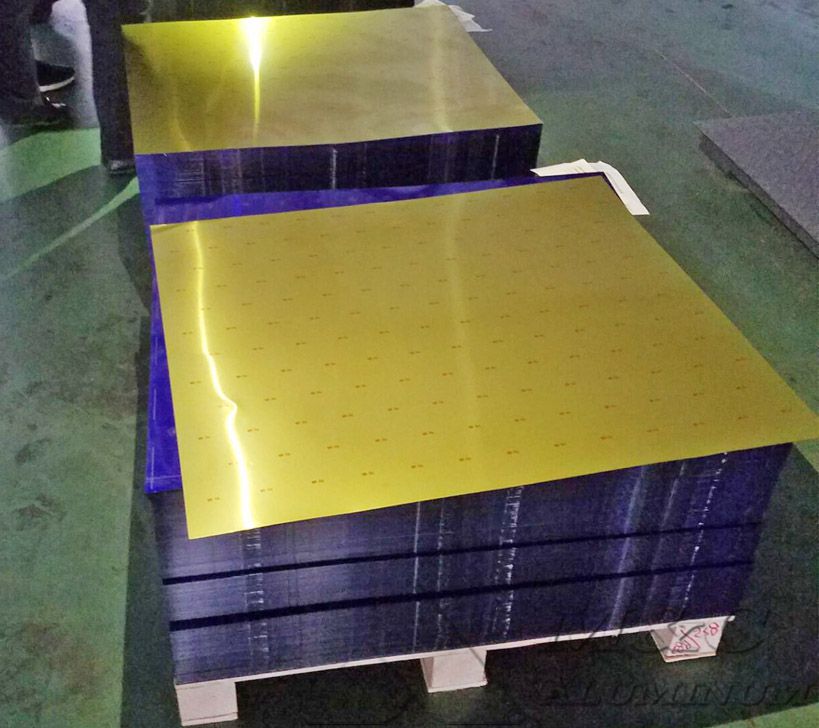

1100 / 8011 alloy for aluminum bottle caps

In the field of bottle cap manufacturing, aluminum bottle caps have become the preferred material for various packaging seals due to their light weight, high strength, good corrosion resistance and excellent processing performance. In particular, 1100 alloy and 8011 alloy occupy an important position in the market with their unique advantages.

1100 aluminum alloy bottle cap material is a bottle cap material made of 1100 aluminum alloy. 1100 aluminum alloy belongs to industrial pure aluminum, and its aluminum content (mass fraction) reaches more than 99.00%, with excellent ductility, formability, weldability and corrosion resistance.

8011 aluminum bottle cap material belongs to 8 series alloy aluminum plate, which is an alloy with Al-Fe-Si elements added, with good deep drawing performance, low ear making rate, light weight, corrosion resistance and other characteristics. After baking in the cap making process, it also has certain strength advantages.

1100/8011 alloy bottle cap material production process:

Smelting, casting, hot rolling, cold rolling, annealing, foil rolling, bending and straightening, slitting and other links

Application areas: widely used in the manufacture of bottle caps for alcoholic beverages (such as white wine, red wine), beverages, cosmetics, milk powder, medicines and other products.

Specifications:

| Alloy | 1100, 8011 |

| Temper | H14/H16 |

| Thickness | 0.18-0.3mm |

| Width | 100-1600mm |

| Length | C |

| Technology | Cold rolling; Hot rolling |

| Coil ID | 75mm, 150mm, 300mm, 500mm, etc |

| Color | Various colors can be provided according to customer requirements |

| Packing details | wooden box or plastic packaging |

| MOQ | 1-3 tons |

Chemical composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99 | |

| 8011 | 0.50-0.90 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Remainder |

1100 Aluminum alloy vs. 8011 aluminum alloy for bottle caps

| Characteristic | 1100 | 8011 |

| Aluminum purity | ≥99% (industrial pure aluminum) | Contains iron and silicon, with lower purity |

| Strength | Lower | Higher |

| Ductility and plasticity | Excellent | Good |

| Corrosion resistance | Excellent | Good |

| Surface treatment performance | General (suitable for simple processing) | Excellent (suitable for coating and printing) |

| Applications | Medical and food bottle caps | Beverage and wine bottle caps |

Currently, the main aluminum bottle cap materials on the market are 1100 alloy, 8011 alloy, etc. Users can choose which alloy to use according to the stretching length of different products.

Quality acceptance standards for 8011/1100 aluminum bottle cap materials:

1. Coil end surface: should be neat, without cracked edges, burrs, warped edges, ruffles, burrs, bumps, etc.

2. Whole roll staggered and tower type: The whole roll staggered should be less than 2mm, and the tower type should be less than 5mm.

3. Surface quality: It should be flat, clean and free of oil spots, and wrinkles and severe indentations are not allowed.

4. Mechanical properties: Mechanical performance indicators such as tensile strength and elongation should meet relevant standards or customer requirements.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan