- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

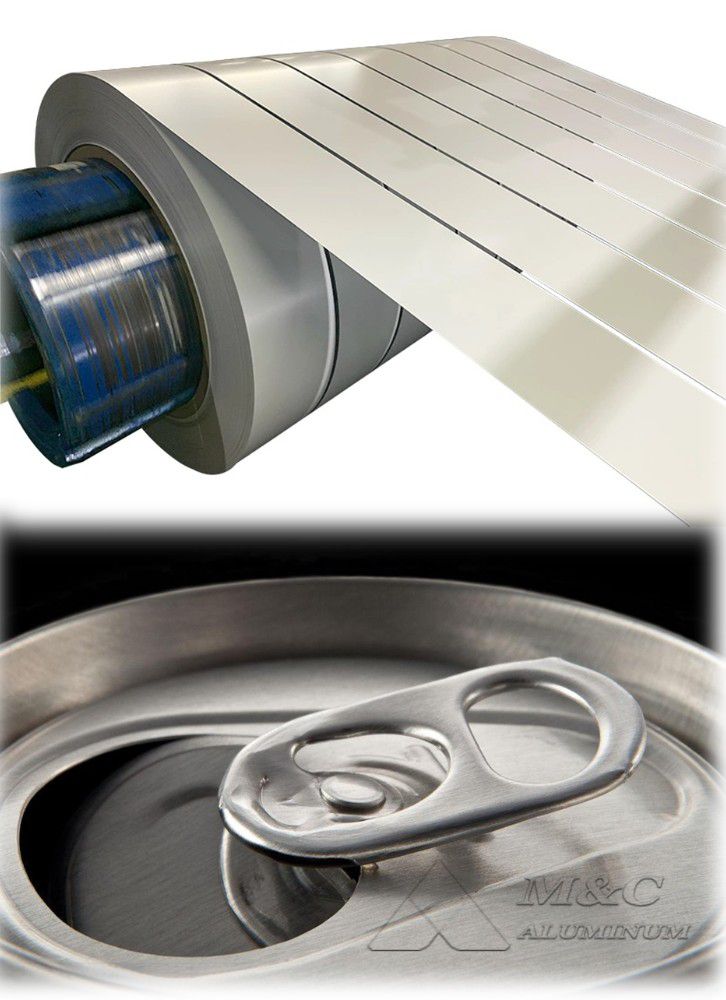

Aluminum strip for can pull tab 5182

The common aluminum alloy cans on the market are composed of three parts: lid, pull ring, and can body. They are made of different alloys, including 5052 lid material, 5182 ring pull material, 3004/3003 can body material, etc. Aluminum alloy easy-open cover material is a non-heat-treatable alloy with good strength, corrosion resistance, good machinability, etc. It has a high surface finish and is very suitable for post-processing such as striping and slicing.

The opening principle of the pull-tab easy-open lid is:

First, pre-make an indentation at the opening of the can lid to reduce its local strength. When opening, a relatively concentrated stress will be generated near the tab. Under the action of shearing force, the indentation will crack and open. Among them, the can pull ring is made of 5182 aluminum strip.

The assembly line process of cans:

Coil conveying → Coil lubrication → Blanking and stretching → Can body forming → Trimming → Cleaning/drying → Stacking/unloading → Coating with base color → Drying → Color printing → Primer → Drying → Inner spraying → Inner Drying → lubrication of the jar mouth → necking → screwing and necking.

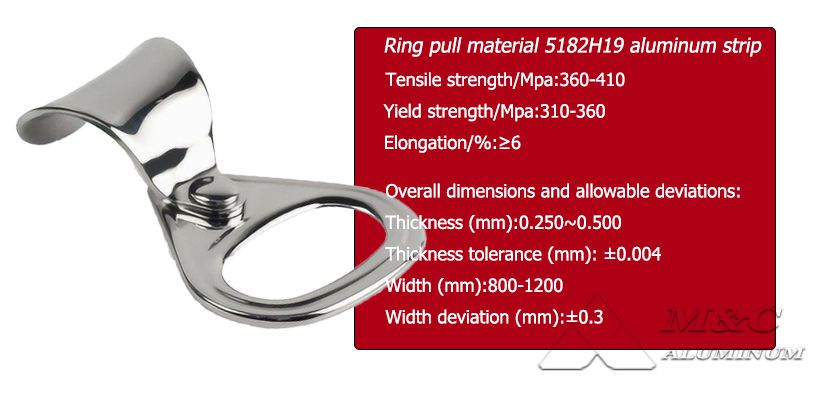

Specifications of 5182 aluminum strip for aluminum alloy bottle cap materials:

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 |

| Thickness | 0.15-0.3mm |

| Width | 20-2650mm |

| Length | 500-16000mm |

Advantages of using 5182 aluminum strip for pull tab materials:

1.Good corrosion resistance

2.Excellent weldability

3. Good cold workability

4. Moderate intensity

5. High tensile strength and yield strength.

MC Aluminum supplies 5182 aluminum strips for can pull rings, 5052 aluminum plates for can lids, and 3003 aluminum plates for can bodies. The thickness is 0.15-600mm and the width is 20-2650mm. It is mainly based on aluminum plates and does not undergo post-processing of finished products. It is exported overseas. Price discount.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan