- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

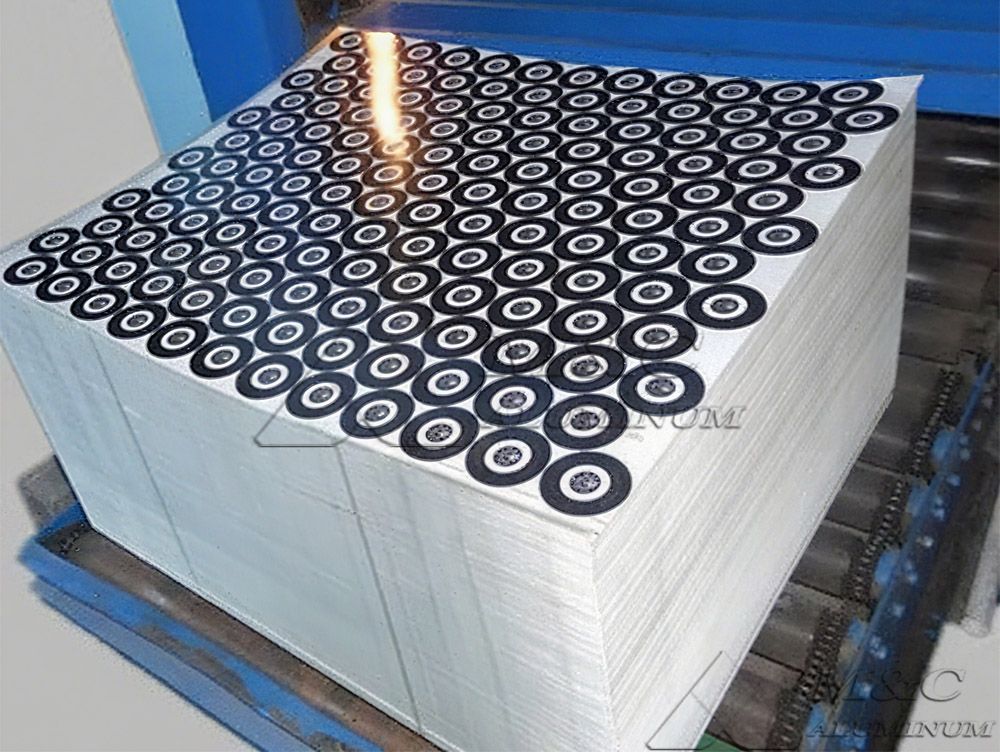

Printed Aluminum Closure Sheet for Anti-Theft Caps

The printed aluminum closure sheet produced by MC Aluminum combines lightweight properties, excellent formability, strong corrosion resistance, and high printability, making it widely used in the production of closures for wine, spirits, carbonated beverages, pharmaceutical bottles, and premium edible oil bottles.

Common Alloys for Pilfer-Proof Caps

Printed aluminum closure sheets for pilfer-proof caps are mainly made from 3000-series and 8000-series aluminum alloys, such as 3105 and 8011. These alloys contain moderate amounts of Mn, Fe, and Si, ensuring sufficient strength while maintaining good ductility.

8011 alloy: Commonly used for bottle caps and packaging foils, featuring excellent barrier properties, formability, and coating adhesion.

3105 alloy: Belongs to the Al-Mn series; stronger than 1000-series pure aluminum, with excellent corrosion resistance, weldability, and processing performance, ensuring the required strength for closures.

Bottle cap aluminum plate product information

| Alloy | 8011 / 3105 |

| Temper | H14, H16, H18 |

| Thickness | 0.15-0.30mm |

| Width | 100-1600mm |

| Length | 100-6000mm |

| Surface quality | Smooth and clean, free from oil stains and scratches, suitable for printing and coating |

| Applications | Screw caps, ROPP caps, wine bottle caps, beverage closures, small bottle caps, etc. |

| Samples | Available |

| MOQ | 1-3 tons |

Advantages of Aluminum Closure Sheet

1. Lightweight: With a density of only 2.7 g/cm³, aluminum closures are lightweight, reducing transportation and logistics costs.

2. High barrier properties: Effectively blocks gases, light, and moisture, preserving the original flavor and stability of beverages and medicines.

3. Aesthetic appeal: Clear printing and high color saturation enhance branding and premium positioning.

4. Anti-counterfeiting functions: Can be combined with holograms, laser coding, or special inks to improve anti-fraud performance.

5. Sustainability: Aluminum has a high recycling rate, aligning with environmental and circular economy trends.

Requirements of Pilfer-Proof Caps for Printed Aluminum Sheets

Strict mechanical properties: High strength, elongation, and dimensional accuracy are required. If not met, cracks or wrinkles may occur during deep drawing.

Superior surface quality: To ensure smooth printing, closure material must be flat and free of roll marks, scratches, or stains. Surface quality directly impacts printing performance and final aesthetics.

Good formability: The aluminum sheet must exhibit excellent deep-drawing properties to meet stamping and forming needs.

Consistent coating adhesion: Surface pretreatments such as chromate or zirconium treatments enhance adhesion of printing inks and protective varnishes.

Production Process of Printed Aluminum Closure Sheet

Base material rolling

Aluminum ingots are cast, hot rolled, and cold rolled to the target thickness, ensuring dimensional accuracy and uniform microstructure.

Surface treatment

Processes such as degreasing, passivation, or pretreatment for coating improve ink and varnish adhesion.

Color printing

Using gravure or offset printing, multi-color designs are applied to the aluminum sheet surface, providing brand identity and anti-counterfeiting effects.

Coating & baking

Epoxy or polyester varnish is applied after printing, followed by baking and curing to form a protective layer, enhancing abrasion resistance and chemical durability.

Slitting & stamping

Large aluminum coils are slit into appropriate widths, then stamped into closure shells using forming equipment.

Why Choose MC Aluminum’s Closure Sheet?

A: Width and thickness tolerances strictly follow process requirements.

B: Surface is smooth, free from cracks, bubbles, pinholes, inclusions, or visible streaks.

C: Surface quality is checked at least once per three coils during rolling, and every coil after final passes.

D: Strict slitting quality control, ensuring no burrs, knife marks, or wavy edges.

As an experienced aluminum bottle cap material manufacturer, MC Aluminum supplies 1100, 8011, 3003, 3105, and 5052 alloys in both foil and sheet form. Our products feature flat surfaces free of roll marks, scratches, and stains. With exports to over 40 countries worldwide, we offer competitive prices, short lead times, and reliable after-sales service—making us a trusted supplier of aluminum closure sheet.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan