- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

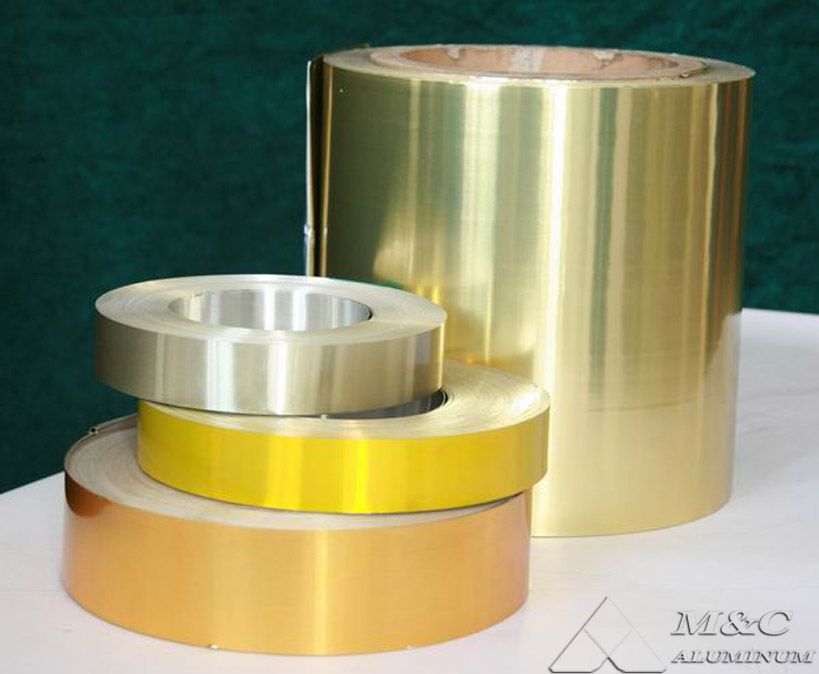

Raw materials for tear-off aluminum caps

The raw materials for tear-off aluminum caps are mainly 8011 alloy aluminum. This alloy aluminum is widely used in the manufacture of various packaging caps that require easy-tear functions, such as medical bottle caps and beverage caps. For example, in the field of pharmaceutical packaging, 8011-H16 aluminum alloy is often used to make aluminum strips, which are then processed into tear-off aluminum caps to meet the special needs of pharmaceutical packaging. In addition, 8011 aluminum alloy has become an ideal material for making full-tear aluminum caps due to its good processing performance and corrosion resistance.

8011 aluminum foil has good processing performance and can be printed, colored, embossed, coated, glued and other secondary deep processing to meet the needs of different customers for the appearance and function of aluminum caps.

Features of pull-cap aluminum caps:

1. Good sealing: Aluminum materials have high plasticity and can fit tightly to containers to prevent air, moisture and microorganisms from entering, extending the shelf life.

2. Excellent barrier properties: Aluminum has excellent barrier properties against oxygen, water vapor and light, protecting light-sensitive and moisture-sensitive products from deterioration.

3. Easy to process and shape: Aluminum alloy materials have good processing properties, adapt to containers of different shapes and sizes, and control thickness and dimensional accuracy.

4. Suitable mechanical properties: The aluminum cap has appropriate strength and hardness, can withstand external forces, and is smooth when torn, making it convenient for consumers to open.

5. Hygiene and safety: Aluminum does not react with the contents under normal use, meets hygiene and safety standards, and protects the health of consumers.

6. Aesthetics and decorativeness: Aluminum caps can be decorated with printing, coating, etc. to enhance product image and brand value.

7. Recyclable: Aluminum materials are highly recyclable, which helps save resources and reduce environmental pressure.

The selection of raw materials for tear-off aluminum caps is crucial, which is directly related to product performance, safety and user experience. The following are specific manifestations of the importance of raw materials:

1. Ensure product sealing and safety:

(1) The pull-off aluminum cap uses high-strength, corrosion-resistant materials (such as 8011 alloy aluminum) to effectively prevent pollution and damage.

(2) Design appropriate opening force to ensure sealing during transportation and storage, and ensure product safety and integrity.

2. Improve user experience:

(1) High-quality raw materials make aluminum lids easy to open, improving consumers' purchasing experience and convenience of use.

(2) The opening force design needs to consider different consumer needs, and appropriate opening force enhances market competitiveness.

3. Guide production process and optimize cost:

(1) Raw material selection affects production process and product quality. Production problems are reflected through opening force testing and other means to provide data support for optimization.

(2) Selecting appropriate raw materials can reduce costs, improve efficiency, and create economic benefits for enterprises.

The quality inspection standards for 8011 aluminum alloy for tear-off aluminum lids mainly include the following aspects:

1. Surface quality: Ensure that the aluminum surface is flat, free of rolling marks, scratches and stains.

2. Thickness uniformity: Use a micrometer to measure, and the tolerance is controlled within the range of ±0.01mm.

3. Mechanical properties: Tensile strength, yield strength, elongation and other tests meet the requirements.

Application fields of pull-off aluminum caps:

Tear-off aluminum caps are widely used in the fields of medicine, food, cosmetics, etc., especially for products that need to be sealed and easy to open. For example, medicine bottle caps, wine bottle caps, milk powder easy-tear caps, canned easy-tear caps, etc.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan