- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

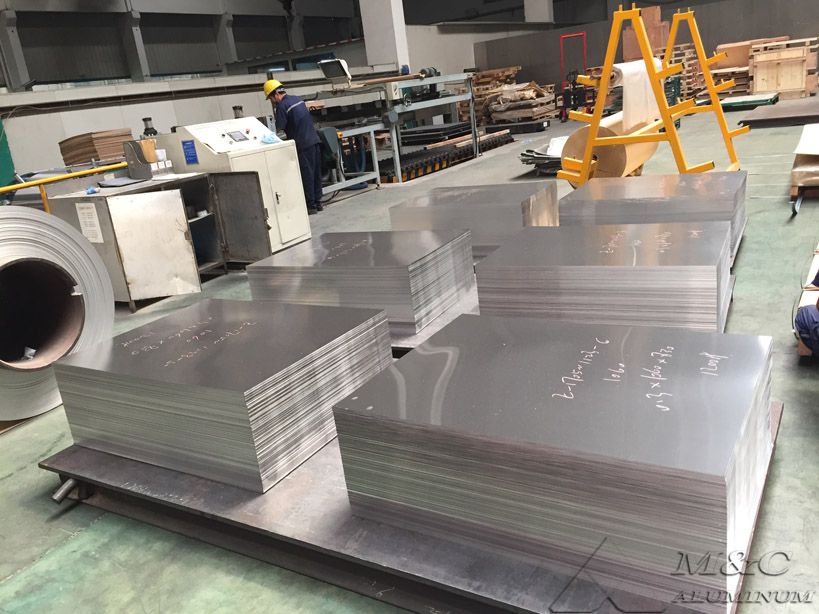

Raw materials of aluminum sheet for bottle caps

Aluminum caps are a common type of caps used for packaging in bottled beverages, cosmetics, medicines and other fields. The main raw materials for aluminum caps are aluminum sheets and coatings. The characteristics of aluminum sheets for bottle caps are light weight, high strength, good corrosion resistance, and recyclability. They are widely used in beverage caps, cosmetic caps, medical caps, wine caps, etc.

Common alloy grades of aluminum sheets for bottle caps include 1060, 8011, 1235, 1070, 5052 and 3105. MC Aluminum provides a thickness range of 0.2-0.5 mm, with an allowable tolerance of ±0.1%, which can be customized according to customer needs. These aluminum alloy materials have good ductility, corrosion resistance and strength, and are suitable for the production of bottle caps.

Specifications:

| Alloy Series | 1 Series | 3 Series | 5 Series | 8 Series |

| Alloy | 1050, 1060, 1235, 1070, 1100 | 3003,3004 | 5052 | 8006, 8011, 8021, 8079 |

| Temper | O, H 16, H18, H19, H24, etc. | |||

| Thickness | 0.014-0.5mm | |||

| Widht | 20-1600mm | |||

| Length | C | |||

Performance characteristics of aluminum sheet for bottle cap

1. Smooth surface: The surface of aluminum sheet is smooth and delicate, which is convenient for printing and decoration.

2. Easy to process: These alloys have good elongation and tensile strength, and are easy to process by stamping, stretching, etc.

3. Good sealing performance: The bottle caps have excellent sealing performance and can effectively prevent liquid leakage.

4. Strong corrosion resistance: Aluminum sheet has good corrosion resistance and can resist erosion by a variety of chemicals.

5. Recyclability: Aluminum sheet is a recyclable material and meets environmental protection requirements.

Aluminum cap production process

The process of aluminum cap production mainly includes: raw material preparation, aluminum sheet processing, paint treatment, drying, stamping, countersunk head, finished product inspection and other links.

Note: The production of aluminum sheets for cap materials can be made by hot rolling or continuous casting and rolling, and then cold rolling.

Raw material requirements for aluminum alloy bottle caps

1.Strength and elongation: Aluminum sheets for bottle caps need to have high strength and elongation to meet the needs of bottle caps during processing and use.

2.Dimension deviation: The dimensional deviation of aluminum sheets needs to be controlled within a certain range to ensure the consistency and interchangeability of bottle caps.

3.Surface quality: The surface of the aluminum sheet should be free of defects such as rolling marks, scratches and stains to ensure the beauty and sealing performance of the bottle caps.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan