- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

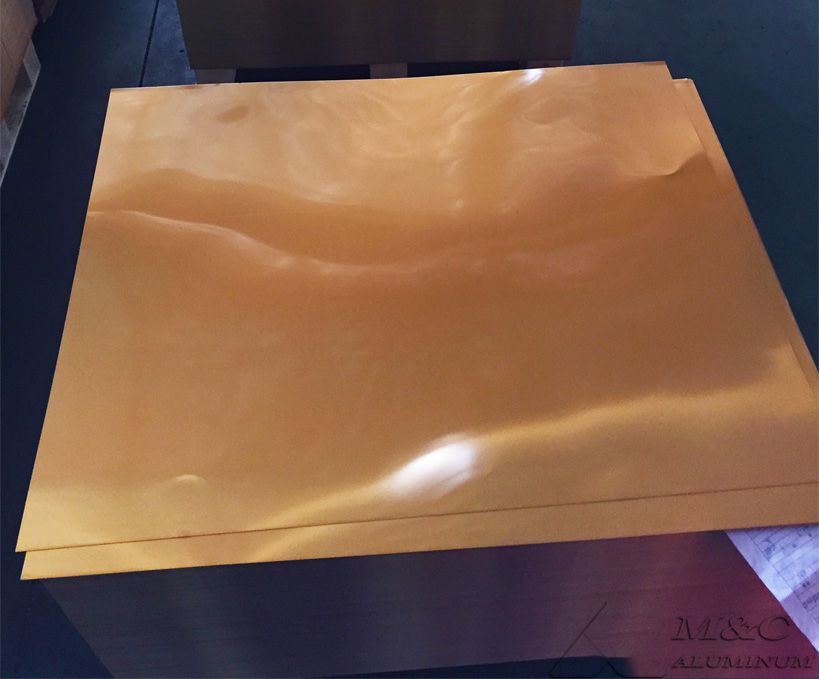

Standards for aluminum plates for bottle caps

Aluminum sheets for bottle caps usually use aluminum alloys such as 3105, 5052, 5182, 8011, 1070, etc., which are used to manufacture various bottle caps (such as food, beverage, and pharmaceutical packaging bottle caps). Specific aluminum alloy sheets usually have good corrosion resistance, ductility, and stamping formability to ensure the sealing and durability of the bottle caps. It is widely used in packaging industries such as beer, carbonated beverages, pharmaceuticals, and cosmetics.

Production process:

The production of aluminum sheets for bottle caps usually includes smelting, casting, hot rolling, cold rolling, annealing, etc. to ensure that its mechanical properties and surface quality can meet the strict requirements of bottle caps.

Performance characteristics of aluminum sheets for bottle caps:

1. Good formability: It must have good tensile strength and elongation to facilitate stamping and stretching during the manufacturing process.

2. Excellent corrosion resistance: It can resist corrosion from various liquids and gases to prevent damage to the bottle caps.

3. Good printability: The surface needs to be flat and flawless to facilitate printing patterns and text.

4. High strength and toughness: It needs to have sufficient strength and toughness to withstand the pressure when opening and sealing.

The aluminum sheet used for bottle caps needs to meet certain standards to ensure that the aluminum sheet can be smoothly formed during the bottle cap processing process, while ensuring the reliability of the finished product in terms of sealing, corrosion resistance and service life. Commonly used aluminum sheet standards include the following:

1. Thickness and dimensional tolerance: The thickness is usually between 0.20-0.23mm, and the thickness and width tolerances are strictly controlled to ensure product stability.

2. Surface quality: The surface is flat, smooth, without scratches, bubbles, cracks, etc., which meets the requirements of food contact materials.

3. Hygiene standards: The aluminum sheet must meet food-grade hygiene requirements to avoid contamination of the bottle contents.

4. Tensile strength and yield strength: Ensure that the bottle cap is not easy to break during the production process and is suitable for stamping.

5. Ductility: The common requirement is ≥3%. High ductility makes the material suitable for deep drawing and stretching, reducing the risk of breakage or deformation.

Related Articles

- 8011 H16 H14 aluminum strip suitable for vial closure

- 8011 Cast-Rolling Aluminum Sheet for Deep-Drawn Wine Bottle Caps

- Why is 3105 Aluminum Sheet the Ideal Choice for Closure Caps?

- 8011 heat-sealed aluminum foil for easy-peel milk powder can lid

- 3105 H14 Aluminum Sheet for Vodka Bottle Caps

- 8011 3105 H14/H16 Aluminum plate for aluminum Ropp closures

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan