- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

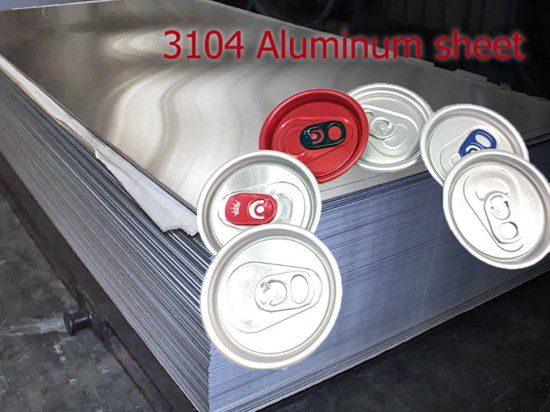

Aluminum closure sheet for can lids

Cans are the most commonly used beverage packaging materials in today's life. There are two materials for making cans: one is aluminum and the other is tinsheet. For environmental protection, the material of cans tends to be aluminum.

The aluminum closure sheet for the can lid is formed by one-time stamping with a punch. The aluminum sheet is plastically deformed to obtain the shape of the can lid through stamping, resulting in optimistic deformation and strengthening, so that the stamped parts have the characteristics of light weight, high strength and good rigidity.

Aluminum alloy can lids are mainly made of 5052 aluminum sheet and 3104 aluminum sheet. The production thickness range is 0.2-5.1mm, and the width range is 50-1600mm.

Specifications of aluminum closure sheets for can lids:

| Alloy | 5052,3104 |

| Temper | H19 |

| Thickness | 0.2-4.5mm |

| Width | 100-2600mm |

| Length | 500-16000mm |

Advantages of aluminum closure sheets for can lids:

1. Good strength, corrosion resistance, good machinability and other characteristics, high surface finish, very suitable for post-processing;

2. Aluminum cans are lightweight, heat-resistant and have good conductivity.

3. Excellent processing performance and good printing effect.

4. Odorless, non-toxic, safe and hygienic, environmentally friendly and recyclable.

Requirements for aluminum alloy sheets for can lids:

Easy-open lid aluminum alloy sheets require high dimensional accuracy and good surface quality, with a thickness tolerance of ±0.005 mm and a width deviation of +1.0-0. In addition, high strength, good formability and uniform performance are required.

Related Articles

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan