- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

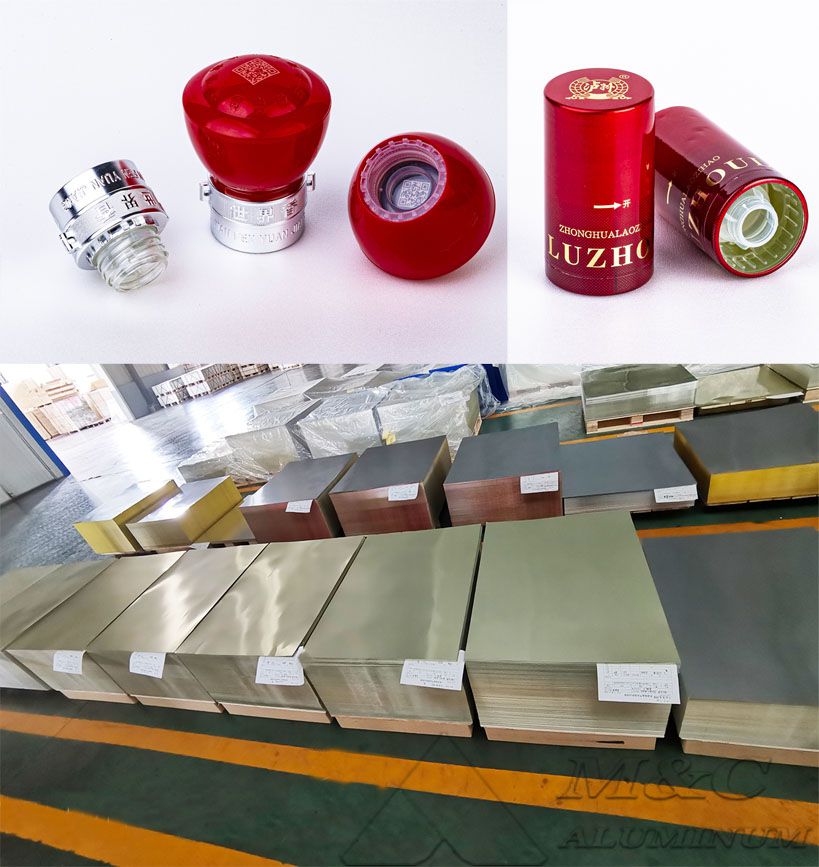

Do you know how bottle caps are produced?

In recent years, in daily life, aluminum bottle caps have gradually become the new favorite in the field of wine and beverage packaging with their unique charm and wide application fields. This seemingly simple bottle cap actually contains exquisite production technology and profound scientific and technological content.

Common alloy models of aluminum bottle caps include 1060, 3003-H16, 3104, 3105, 5052, 5182 and 8011-H14. They are widely used in wine bottle caps, beverage caps, milk powder caps, dry goods easy-pull caps, can caps, etc. These alloy models have different characteristics and uses, for example:

(1) 1060 aluminum sheet: The aluminum caps made are exquisite and widely used in the packaging of wine, beverages (including gas and non-gas) and medical and health products, which can meet the special needs of high requirements such as high-temperature steaming and sterilization.

(2) 3003-H16 alloy: often used in situations where the bottle cap needs to be easy to print after forming, and the material plate surface needs to be flat, without rolling marks, scratches and stains.

(3) 5052 alloy: performs well in can lids, and also has the characteristics of light weight and portability, excellent corrosion resistance and sealing.

(4) 5182 alloy: can be ultra-thin and high-strength, as thin as 0.208mm, and is a representative of high technology.

(5) 8011-H14 alloy: is also one of the commonly used alloys for aluminum bottle caps, with good processing performance, sealing, easy stamping and high strength. Widely used in wine bottle caps, beverage caps, milk powder caps, dry goods easy-to-pull caps, etc.

Multiple advantages of aluminum caps:

1. Superior performance and good processing performance:

Aluminum is easy to process and adapt to different packaging needs.

Strict strength and size standards to avoid cracks and creases.

2. Good sealing:

Excellent sealing performance, suitable for high temperature sterilization, ensuring product quality.

Especially suitable for packaging that requires strict sealing, such as alcoholic beverages.

3. Easy to print, good visual effect:

Aluminum caps are easy to print, with consistent color and exquisite patterns.

Provide personalized artistic creation space to meet the diverse needs of the market.

4. Good environmental protection effect and high recycling rate:

High recycling rate, reducing environmental pollution, meeting environmental protection requirements.

Compared with plastic caps, the production cost is low and pollution-free, which is in line with sustainable development.

Strict production requirements for aluminum bottle caps:

The production of aluminum bottle caps usually relies on highly automated production lines, which places extremely high requirements on the strength, elongation and dimensional accuracy of the material. If the material quality is not up to standard, it may break or crease during processing, affecting production efficiency and product quality.

Aluminum alloy bottle cap materials must meet the following requirements: the surface of the material plate is flat, without rolling marks, scratches and stains. Most domestic manufacturers use continuous casting and rolling billets as raw materials for bottle caps. The performance of this material is significantly better than that of traditional cast and rolled billets, with higher processing adaptability and better product performance.

MC aluminum is a large-scale aluminum foil substrate production factory for bottle caps. It can produce 8011 aluminum foil, 1060 aluminum foil, 1235 aluminum foil, 3104 aluminum plate, 5182 aluminum plate, etc. The products are grade A in water brushing and have a low ear-making rate. We accept orders of 1-200 tons, with affordable prices, overseas exports, short delivery time, free samples, and guaranteed after-sales service.

-

Advisory Message

Alloy Grade Thickness, Application, etc.

-

Quick Reply

Quick reply within 30 minutes

-

Getting Information

One-to-one design and customized production plan