- Address:Zhengzhou, Henan, China

- Mon-Fri (8am - 6pm)

- sales@alummc.com

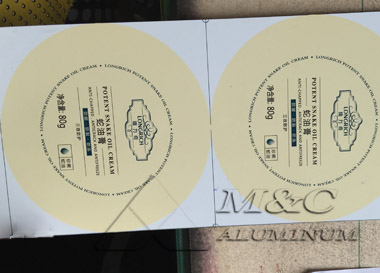

Coated Aluminum Foil for closure lid

2025-04-22

Bottle cap aluminum foil typically uses 8011 aluminum alloy (such as H14, H16, H18 temper) with a thickness range of 0.006-0.5mm.

Aluminum closure sheet

2023-12-12

Aluminum lid closure sheets are used to seal various glass bottles and jars such as soft drinks and nutritional drinks to meet customer needs for protection of container contents, easy opening and very convenient sealing.

8011 Aluminum foil bottle cap material

2024-01-18

Aluminum alloy bottle cap materials are widely used in the food, beverage industry, alcohol, chemical industry, medicine and other fields. They have moisture-proof properties, light-shielding properties and high barrier capabilities.

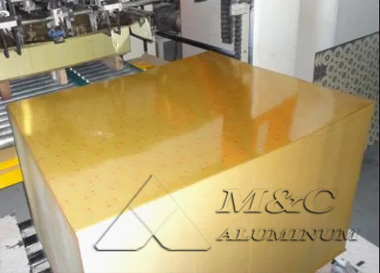

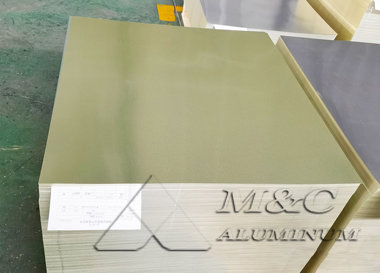

AA8011 Aluminum Sheets / Coils for PP Caps

2025-11-04

MC Aluminum's 8011 aluminum sheets and coils are produced using roll coating technology, resulting in a smooth and flat surface with very few defects, making them ideal for printing and coating processes.

Aluminum closures for bottle cap sealing

2024-04-17

Aluminum closures play an important role in bottle cap sealing and have been widely used in sealing packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc. at home and abroad. This material not only has a beautiful appearance

Aluminum bottle cap material manufacturer

2024-01-08

Aluminum and aluminum alloy bottle cap materials are a new type of bottle cap sealing material. They are not only beautiful and easy to open, but also have the function of preventing counterfeit goods. Therefore, it has been widely used in the sealing pac

25mm Anti-theft aluminum bottle cap material supply

2024-04-23

8011 3033 anti-theft aluminum bottle cap material has become an important choice in the modern packaging industry with its excellent performance, environmental protection, safety and good processability.

Medicinal aluminum bottle caps

2024-11-19

Medicinal aluminum bottle caps are an indispensable sealing material in modern pharmaceutical packaging, which not only ensures the safety and quality of drugs, but also improves the convenience and reliability of use.

What kind of aluminum alloy is the aluminum alloy bottle cap

2024-11-22

Aluminum alloy bottle caps are usually made of a variety of different types of aluminum alloy materials, mainly 1 series, 3 series, 5 series and 8 series aluminum alloys.

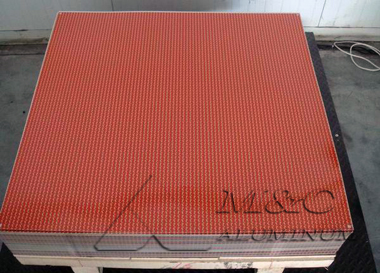

Factors affecting color-coated aluminum closure sheet

2024-05-14

Color-coated aluminum bottle caps have the advantages of stable performance, not easily corroded, and easy to open, which make them widely used in packaging in alcohol, beverage, medicine, cosmetics and other industries.

Importance of aluminum alloy bottle caps in life

2024-11-15

The general alloy state of aluminum bottle caps is 8011-H14, 1060, 3105, 5182, 5052, etc., and the material specifications are generally 0.17mm-0.5mm thick and 449mm-796mm wide.

Aluminum Closure Sheet for Metal Caps

2025-04-01

Aluminum bottle cap material not only has good deep drawing forming performance and low anisotropy but also maintains a certain baking strength after multiple color printing and curing processes.

8011 H14 hot rolled aluminum alloy bottle cap material

2024-02-02

Aluminum bottle caps are made of finely processed high-quality aluminum closure sheets. They have the characteristics of good closure, easy opening, and the function of preventing counterfeit goods. They have been widely used in beverage bottles, wine bot

Hot rolled A8011 H16 aluminum strip for high performance anti-theft caps

2025-10-21

Hot-rolled 8011 H16 aluminum strip meets the stringent requirements of deep drawing, spinning, embossing and printing processes, and is widely used in the production of anti-theft bottle caps and beer caps.

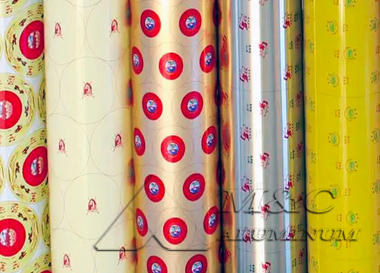

Printing aluminum bottle cap material

2024-11-05

Printing aluminum bottle cap material mainly refers to the printing alloy material used to make bottle caps. It usually uses high-quality aluminum alloys, including 8011 aluminum foil, 1060 aluminum coil, 3105 aluminum coil, etc. These alloys have good ph

Price of 3105 aluminum coil for aluminum bottle cap

2024-10-12

Aluminum bottle cap material is a new type of bottle cap sealing material. It is widely used in packaging of food, beverage, medicine, cosmetics and other industries because of its beautiful appearance, easy opening, and the function of preventing counter

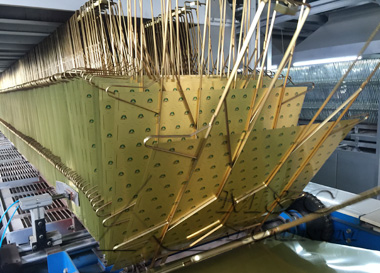

Aluminum closure cap production process

2024-09-05

Aluminum bottle cap material can be produced by hot rolling or continuous casting and rolling process. Hot rolling is usually used to produce thick aluminum plates, which are then cold rolled to make bottle cap materials. The continuous casting and rollin

Aluminum bottle cap material 8011-h18 aluminum foil

2025-01-17

8011-H18 aluminum foil refers to aluminum foil material used to seal various bottle mouths. With its high strength, moisture resistance, corrosion resistance and excellent processing performance,......

High quality requirements for aluminum plates for bottle caps

2024-09-13

MC Aluminum is an aluminum bottle cap ma

Aluminum bottle cap materials that are everywhere in life

2024-11-29

Aluminum bottle cap materials are very common in life. The main application areas of aluminum bottle cap materials are: aluminum for cosmetic bottle caps, aluminum for can bottle caps, aluminum for wine caps, aluminum for medical bottle caps, etc. In the

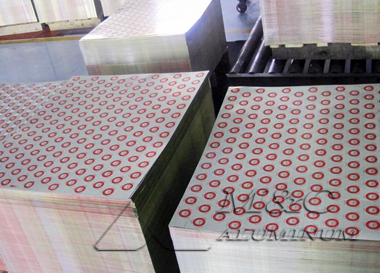

Color Coated Aluminum Sheet for Bottle Caps

2025-10-10

Colored aluminum plate bottle caps are based on 3105, 8011, 5052, 1060 aluminum alloy plates and are used for bottle caps of soft drinks, alcohol, cosmetics, medicines, etc.

Printed Aluminum Closure Sheet for Anti-Theft Caps

2025-09-12

The printed aluminum seals commonly used for anti-theft caps are mainly 3000 and 8000 series aluminum alloys, such as 3105 and 8011. They are widely used in the production of bottle caps for wine, spirits, carbonated beverages, and pharmaceuticals.

Aluminum substrate for bottle caps

2024-12-27

MC Aluminum develops and produces various types of aluminum bottle caps, such as 1060 aluminum plate, 3104 aluminum plate, 5052 aluminum plate, 8011 aluminum foil, etc.

Printed aluminum sheets for bottle caps

2024-09-09

Printed aluminum sheets are often used in the production of bottle caps, especially in the food, beverage, pharmaceutical and other industries. Aluminum sheets hav

3105 Aluminum Coil for Vial Seals

2025-11-21

Common bottle cap material states for 3015 aluminum sealing plates used for small bottle sealing include O temper (annealed), H18, H24, H26, etc., which have good formability, ductility and corrosion resistance.

3105 Red Wine Aluminum Bottle Cap VS Traditional Oak Cork

2024-10-22

In daily wine drinking, we will find that some wine bottles are sealed with corks and some with screw caps. Is there any difference between the two? The following content is introduced in detail:1. MaterialAluminum bottle cap: usually made of 3105 aluminu

Aluminum Foil Manufacturer for Anti-Theft Bottle Caps

2025-03-11

Aluminum foil for anti-theft bottle caps often uses alloy numbers such as 8011-H14, 1060, 1235, 3003-H16, 3004, 3104, and 3105.

3105 8011 printed aluminum plate for bottle cap anti-counterfeiting

2025-02-21

The alloy numbers of printed aluminum plates used for bottle cap anti-counterfeiting mainly include 8011 and 3105 materials.

Aluminum Alloy Bottle Cap Material: 3105 Aluminum Coil

2025-04-08

In the modern packaging industry, 3105 aluminum coil has become widely used in packaging containers for food, beverages, and pharmaceuticals due to its advantages of light weight, aesthetics, corrosion resistance, and recyclability.

Coated aluminum foil for bottle caps

2023-12-18

The surface of the coated aluminum foil used for bottle caps is free of oil stains, dents, inclusions, scratches, stains and other defects that affect use.